It can be used in various fields. Working distance is about 100m.

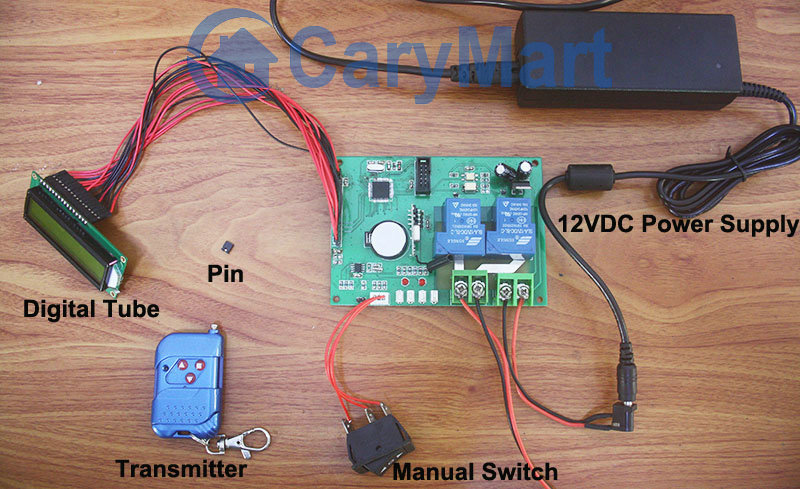

This is circuit board can be a reversing controller, with forward-reverse-stop capability. You can rotate the motor in positive or reversal direction with the transmitter (remote control) from any place within a reliable distance and wireless RF signal can pass through walls, floors and doors. It can be controlled by maunal switch or transmitter. But now only DC power is available. It is suitable for the DC motors of blind, rolling door, projection screen, awning, winch or other appliances and mechanicals.

The remarkable characteristic is “Time Remote Control”, if you preset working and stop time for device and time is up, the being controlled device will work and stop according to your setting.

Suppose that the real time of setting is 14:56, February, 19th 2014, Wednesday.

Press S1, controller enters into the status of “date and time setting”.

Press S1 again to set “Year” to “2014”.

Press S1 again to set “Month” to “02”.

Press S1 again to set “Date” to ”19”.

Press S1 again to set “Hour” to “14”.

Press S1 again to set “Minute” to ”56”.

Press S1 again to set “Week” to” 3”.

The correspondent data will flash when we are setting. Then, press S2(+) or S3(-) to adjust according to your need. Press S1 again to save data and log out automatically when week setting is finished. After setting, we can see the following picture. The LED digital tube will read those data.

Video:

Follow

Follow