We have set and saved the following data previously:

15:10 Motor rotates in positive direction. (The first operation), that is (W:3 C:1 R:+ WORK).

15:11 Motor stops. (The second operation), that is(W:3 C:2 R:0 WORK).

15:12 Motor rotates in reverse direction.(The third operation), that is (W:3 C:3 R:- WORK).

15:13 Motor stops. (The fourth operation), that is(W:3 C:4 R:0 WORK).

Everything is done. DC motor is ready to work when time is up.

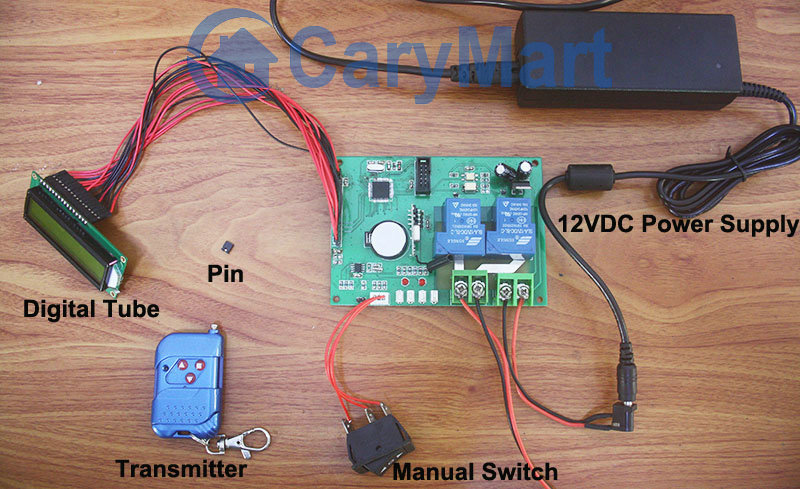

When the real time is 15:10, motor rotates in positive direction. At the bottom of the tube screen, it displays the next operation at this time.

W:3 (Wednesday) C:2 (The second operation) R:0(stop) WORK

When the electronic clock reads 15:11, motor will stop.

When the real time is 15:11, motor stops. At the bottom of the tube screen, it displays the next operation at this time.

W:3 (Wednesday) C:3 (The third operation) R:- (reverse direction) WORK

When the electronic clock reads 15:12, motor will rotate in reverse direction.

When the real time is 15:12, motor rotates in positive direction. At the bottom of the screen, it displays the next operation at this time.

W:3 (Wednesday) C:4 (The fourth operation) R:0(stop) WORK

When the electronic clock reads 15:13, motor will stop.

When the real time is 15:13, motor stops. All operations are finished successfully.

Vdieo:

Follow

Follow