This kind of inversion momentary motor controller (S1FM-AC220 & CV-2-2) features in controlling ac motor of rolling blinds/ doors, window cover, projection screens, awnings, water pump, winches, conveyors or other appliances and mechanicals. It can always keep motor running in positive or reversal position if pressing and holding button ▲ or ▼ on remote or receiver. If you release the button, motor will stop. Its transmission distance is about 500m/1500ft theoretically.

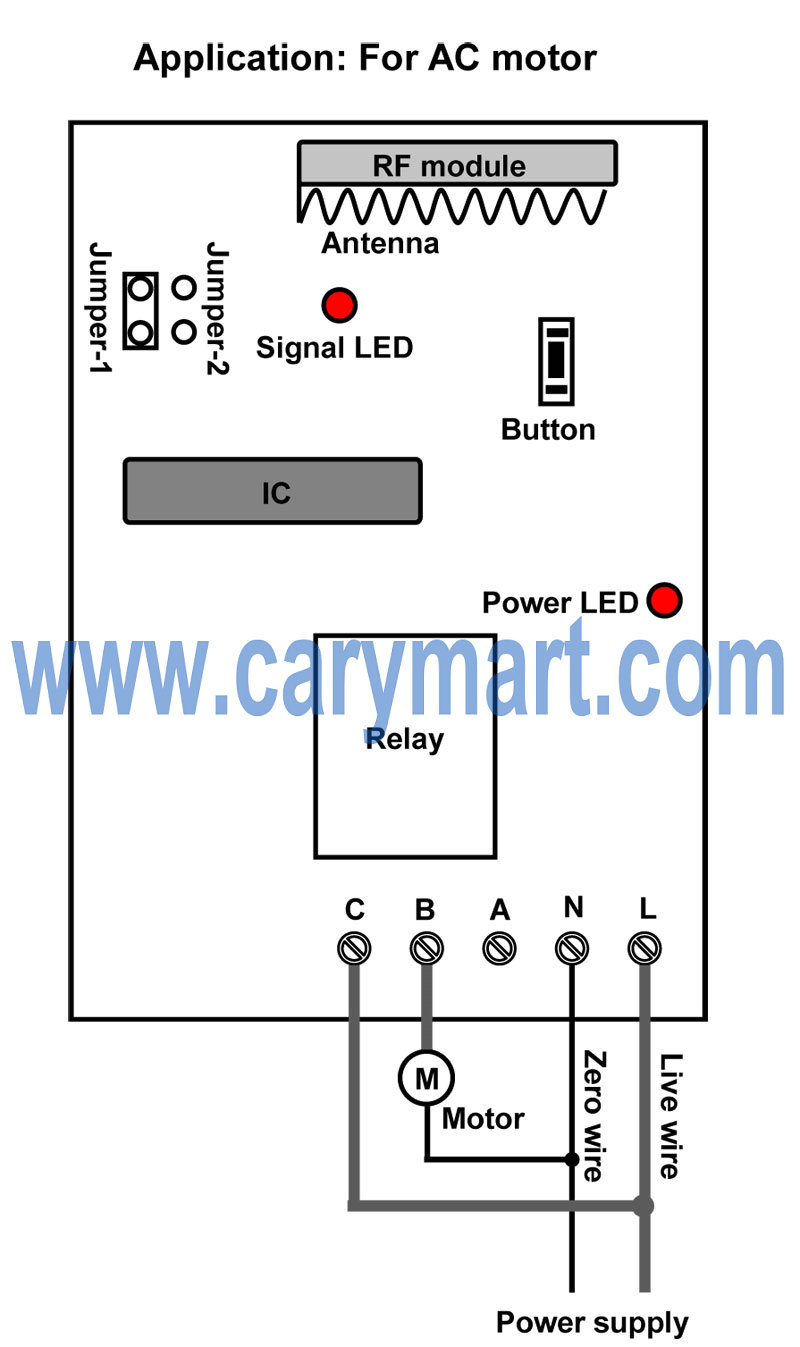

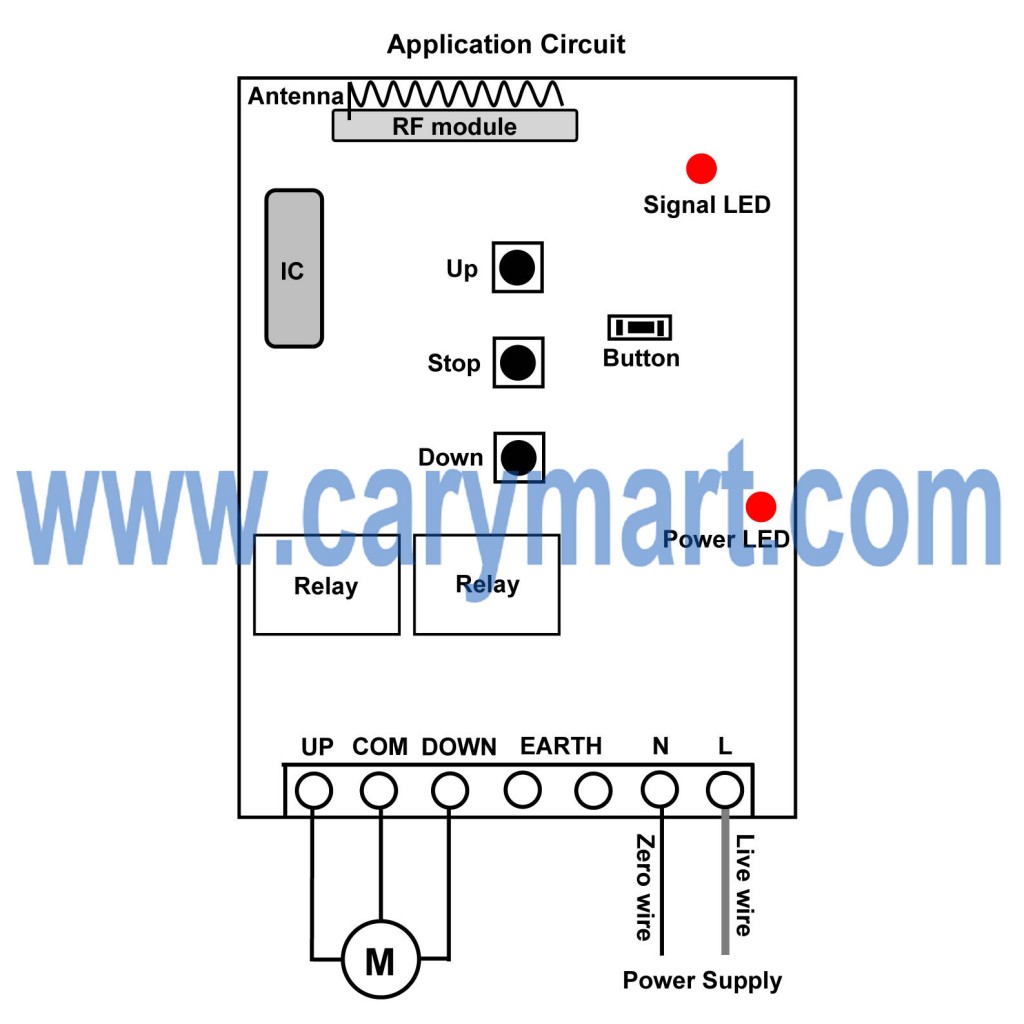

We’d like to show you how to wire and control AC motor.

We show prepare the following material:

1×Transmitter (CV-2-2)

1×Receiver (S1FM-AC220)

1×AC Motor

220V Power Supply

Wires

At first, we connect live wire to terminal “L” and neutral wire to terminal “N”. Then connect AC motor to terminals “UP”, “COMMOM” and “DOWN”. You can exchange “UP” and “DOWN” wires of motor to change the rotating direction of motor. Add power supply to receiver.

Press and hold button ▲ on remote or receiver: Terminals UP and COMMOM directly output AC110V / AC220V; motor rotates continuously in positive direction.

Release button ▲ on remote or receiver: Stop the motor.

Press and hold button ▼ on remote or receiver: Terminals DOWN and COMMOM directly output AC110V / AC220V; motor rotates continuously in reversal direction.

Video:

Follow

Follow