In industry, agriculture and daily life, water for the processing of beverages and foodstuffs, water for chemical production and domestic water supply, etc. People usually use pumps and tanks to form a pumping system. Earlier, people used manual control systems to control the water level in pumps and tanks. Later people used water level sensors and wired controls to automatically control the water level in pumps and tanks. For example, when the water level in the tank is too low, the pump is automatically activated to pump water to raise the water level; or, when starting the motor pumping water, the water pump is automatically shut down once the water level in the tank reaches the proper level. Now we can use more innovative wireless control technology to achieve wireless automatic control of water levels in pumps and tanks. The wireless control system is usually suitable for pump far away from the water tank occasions.

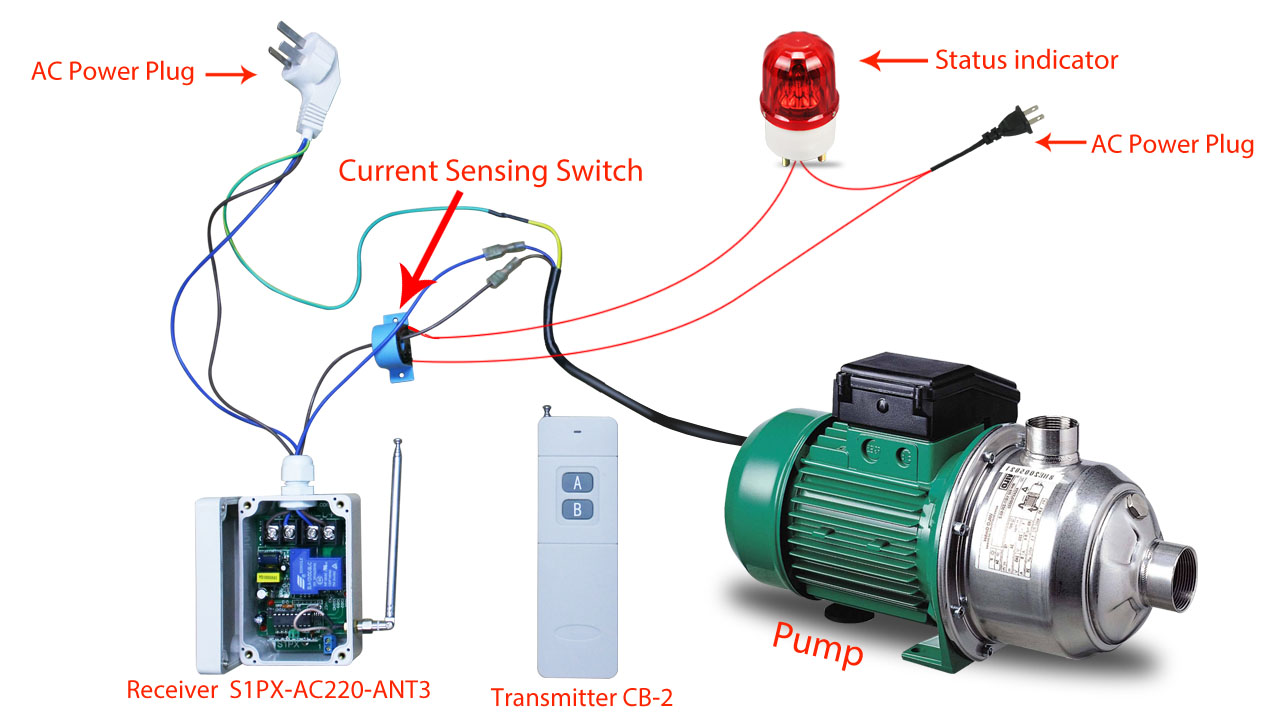

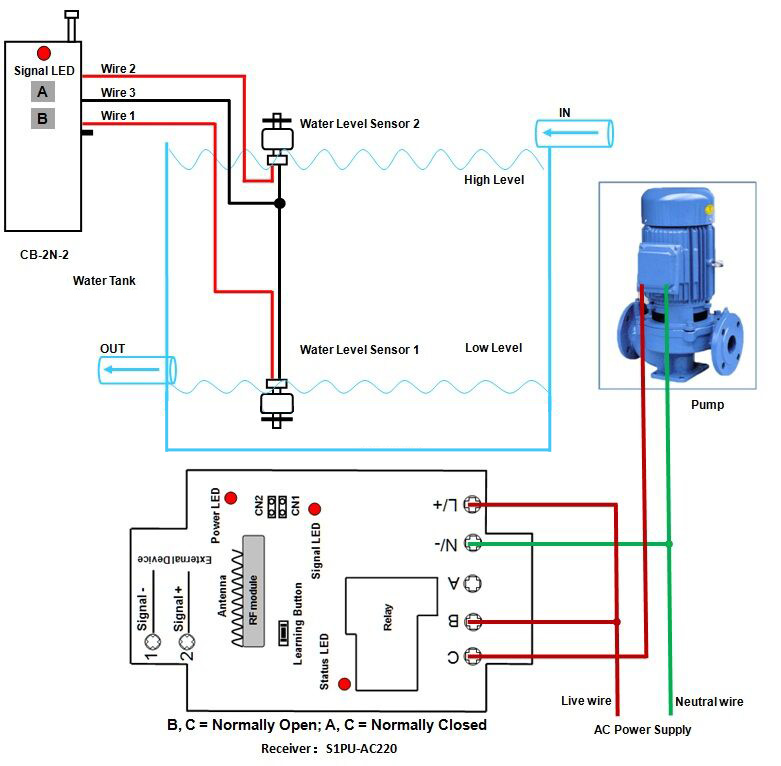

One of our clients told us his trouble. He wanted to control a reasonable pumping level. But the pump was about 100M away from the water tank. He didn’t want to connect a control line from the water tank to the water pump. He found it inconvenient so that he doesn’t consider the traditional wired control solution. He asked us to provide a solution for the radio frequency wireless control system. So we customized a wireless water level automatic control system, the model is 0020525. The system includes a wireless receiver (model S1PU-AC-ANT3, a transmitter (model CB-2), a dry contact transmitter (model CB-2N-2), and two wired water level sensors. The dry contact transmitter CB-2N-2 has three input lines which used to connect two water level sensors. The Receiver Wireless S1PU-AC-ANT3 can be used at 110V, 120V, 220V, 240V and has a relay output for connection to the pump. The receiver has a waterproof case and an external telescopic antenna that can be installed in outdoors. Two wired water level sensors are normally open/dry contact, and they are installed in the water tank. One is installed at a high water level (with the sensor facing up) and the other one is installed at a low water level (with the sensor facing down). This system uses a water level sensor to detect changes in water level and a water level sensor triggers the transmitter to automatically transmit a wireless signal. The receiver receives the signal and automatically turns the pump on or off. This system uses the water level sensor to detect the water level range. The water level sensor triggers the transmitter to automatically transmit the wireless signal according to the set value, and the receiver decoding signal automatically instructs the water pump to turn on or off.

The working principle of the transmitter (model CB-2N-2):

When the transmitter’s input lines 1 and 3 are connected, it automatically transmits a “NO” wireless signal, which is equivalent to the function of the button “ON” on the transmitter.

When the transmitter’s input lines 2 and 3 are connected, it automatically transmits an “OFF” wireless signal, which is equivalent to the function of the button “OFF” on the transmitter.

The working principle of the receiver (model S1PU-AC220-ANT3):

When the receiver receives a “NO” or “OFF” wireless signal, it can actuate its relay to turn the connected pump on or off.

The working principle of Wire water level sensor:

The water level sensor has two lines, they are normally open. When the sensor is triggered, these two lines will be connected to power.

Diagram:

When the float is in this state, the two lines are connected.

When the float is in this state, the two lines are disconnected.

The working principle of the water level automatic wireless control system:

When the water level in the water tank is lower than the position of the water level sensor 1, two lines of the water level sensor 1 are connected to trigger the transmitter CB-2N-2 to send the RF wireless signal “ON”. When the receiver S1PU-AC-ANT3 receives this signal, it triggers the relay to turn on the pump, which starts pumping water into the tank.

When the water level in the water tank rises to the position of the water level sensor 2, the two wires of the water level sensor 2 are connected to trigger the transmitter CB-2N-2 to send the RF wireless signal “OFF”. When the receiver S1PU-AC-ANT3 receives this signal, it triggers the relay to turn off the pump.

You can also turn the pump on or off at any time by pressing the two buttons on the transmitter / remote CB-2.

When the pump is far away from the tank, we can use this automatic water level control if it is inconvenient to use a wired control series to control the pump. The sensors are wirelessly connected to the receiver, and RF signals can pass through walls, trees, and other obstacles. We no longer need to connect a wired control cable from the tank to the pump. This type of RF wireless control system consists of a normally open contact transmitter and receiver. The transmitter can be connected to a variety of normally open / normally closed output devices, such as the alarm host, cable detectors, sensors, limit switches, PLC programmable logic controller. The receiver can be connected to a variety of DC / AC equipment, such as alarm speakers, lights, motors, motors, electric doors and so on. This set of normally open contactless wireless remote control device mainly uses a device with normally open / normally closed output to wirelessly control another AC or DC device. It can be used in many applications such as water level control in tanks, automatic remote control of industrial equipment and simultaneous remote control of agricultural equipment.

Follow

Follow