Wireless remote control technology has been very widely used. Whether it is satellites or household appliances mostly can be controlled by wireless remote control technology. RF control can fully liberate people from complicated manual labor, and wireless operates any electronic equipment at a distance as much as they want. The development of wireless remote control technology make people enable to enjoy the charm of science, also reduce labor intensity, improve labor productivity, and improve job safety. Crane is mainly used to load and unload objects, widely used in construction sites, commercial, factories, farms, supermarkets, and other occasions. Using wireless remote control technology can achieve crane wireless control. Crane wireless remote control system has the following advantages.

1. Reducing manpower costs. For cranes, truck cranes and other equipment, the operator can operate the equipment along with the wireless remote control technology, and no longer need the assistance of other people. Also, the single person can manage a number of cranes, so the operator is able to control the other equipment while manipulating the crane simultaneously.

2. Increasing the efficiency of operation. Because the operator can operate the equipment alone, it improves the accuracy and efficiency of the operation, avoids misunderstandings between the device operator and the ground commander, and applies to the precise installation operation such as equipment assembly.

3. Improve the environmental safety. When a worker operates equipment in toxic gas, high temperature, dusty and dangerous place, the operator can choose the environment that is suitable and safe to operate the equipment, the operator’s personal safety is protected, and the operation conditions have been improved.

Different types of cranes require different wireless control systems. When we use a wireless control system to control the single-phase crane, it is necessary to change the original control circuit of the single-phase crane. The scheme is simple and easy to do. For example, see Figure 1 below:

The single-phase crane is composed of a wired control handle, an emergency button, a limit switch, a fan, an AC motor (with a starting capacitor), a winch and a wire rope. The principle of the work is to use the forward and reverse rotation of the motor to drive the winch, and to make the wire rope be extended or retracted. The electrical schematic of this single phase crane is shown in Figure 2:

According to the electrical diagram of the wired control handle, we recommend a set of the wireless remote control system, the receiver model is 0020451 (S6C-AC220), the remote control model is 0021004 (C-3-2). The S6C-AC220 receiver in AC 100~240V power supply, it has 6 relay output (normally open and closed type), which has two kinds of control mode (momentary mode and interlock mode). The remote C-3-2 has three buttons (▲,▼,▇) with protective cover. The wireless control system can achieve the maximum distance of 100 meters in the open area. If you want to further control the distance, you can connect an external antenna to the receiver and use another high power remote controller, the model is 0021047 (CB-3-2).

The wireless remote control system installation process is as follows:

1. The receiver S6C-AC220 has 6 relay outputs. We need to change the receiver’s circuit so that the ▲ button of the remote control can simultaneously control the 3 relays on the left, and the ▼button can simultaneously control the 3 relays on the right. Circuit modification is shown in Figure 3 below :

2. We analyze the role of each line in the wired control handle, the wired control handle shown in Figure 4 below:

Based on the analysis of the wired control handle and the crane electrical diagram, we know the function of all wires on the wired control handle, as shown in Figure 5 below.

Based on the analysis of the wired control handle and the crane electrical diagram, we know the function of all wires on the wired control handle, as shown in Figure 5 below.

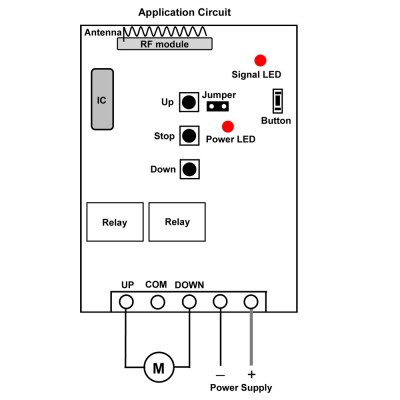

3. Use the receiver instead of the wired control handle, and the original wired control handle must be removed. The connection between the receiver and the motor is shown in Figure 6 below.

3. Use the receiver instead of the wired control handle, and the original wired control handle must be removed. The connection between the receiver and the motor is shown in Figure 6 below.

1. The receiver is set into a momentary mode, and the operation process is as follows: Press and hold the button ▲ on the transmitter: The relays 2, 4 and 6 are activated, the crane rotates in a positive direction. Release button ▲ on the transmitter: The relays 2, 4 and 6 are deactivated, the crane stops working. Press and hold the button ▼ on the transmitter: The relays 1, 3 and 5 are activated, the crane rotates in reversal direction. Release button ▼ on the transmitter: The relays 1, 3 and 5 are deactivated, the crane stops working. 2. The receiver is set up to latched mode, and the operation process is as follows: Press button ▲ on the transmitter: The relays 2, 4 and 6 are activated, the crane rotates in a positive direction. Press button ■ on the transmitter: The relays 2, 4 and 6 are deactivated, the crane stops working. Press button ▼ on the transmitter: The relays 1, 3 and 5 are activated, the crane rotates in reversal direction. Press button ■ on the transmitter: The relays 1, 3 and 5 are deactivated, the crane stops working. One of our customers used our wireless remote control system to make a set of wirelessly controlled elevator with the following video.

1. The receiver is set into a momentary mode, and the operation process is as follows: Press and hold the button ▲ on the transmitter: The relays 2, 4 and 6 are activated, the crane rotates in a positive direction. Release button ▲ on the transmitter: The relays 2, 4 and 6 are deactivated, the crane stops working. Press and hold the button ▼ on the transmitter: The relays 1, 3 and 5 are activated, the crane rotates in reversal direction. Release button ▼ on the transmitter: The relays 1, 3 and 5 are deactivated, the crane stops working. 2. The receiver is set up to latched mode, and the operation process is as follows: Press button ▲ on the transmitter: The relays 2, 4 and 6 are activated, the crane rotates in a positive direction. Press button ■ on the transmitter: The relays 2, 4 and 6 are deactivated, the crane stops working. Press button ▼ on the transmitter: The relays 1, 3 and 5 are activated, the crane rotates in reversal direction. Press button ■ on the transmitter: The relays 1, 3 and 5 are deactivated, the crane stops working. One of our customers used our wireless remote control system to make a set of wirelessly controlled elevator with the following video.

Follow

Follow