Heavy duty dc motor controller features remote control, manual switch and limit switch function. It is capable of controlling DC motors of rolling blinds / doors, projection screens, awnings, pumps, winches, conveyors or other appliances and mechanicals with voltage DC12V / 24V. Motor can be rotated in positive or reversal direction with the transmitter (remote control) or manual switch on the receiver or limit switch from any place within a reliable distance; the wireless signal can pass through walls, floors and doors.

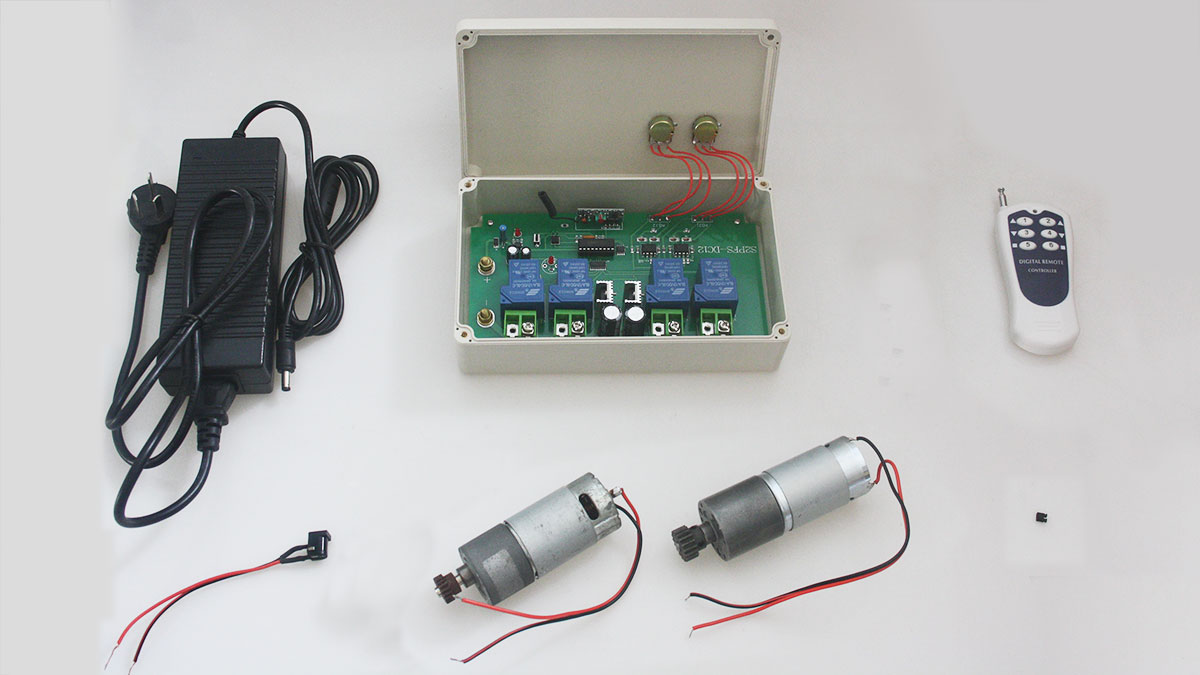

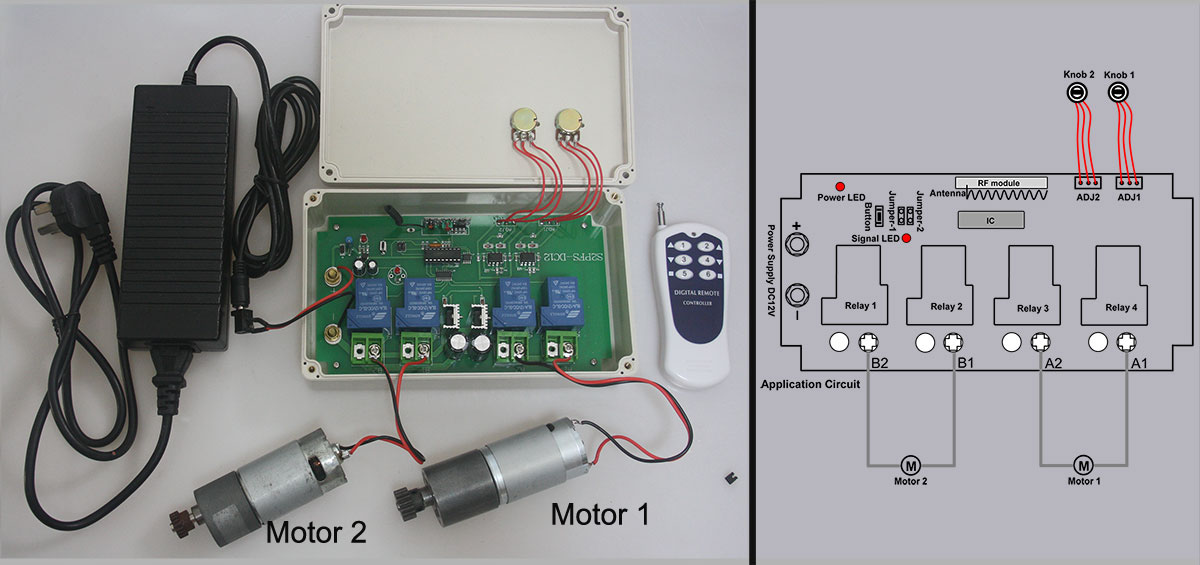

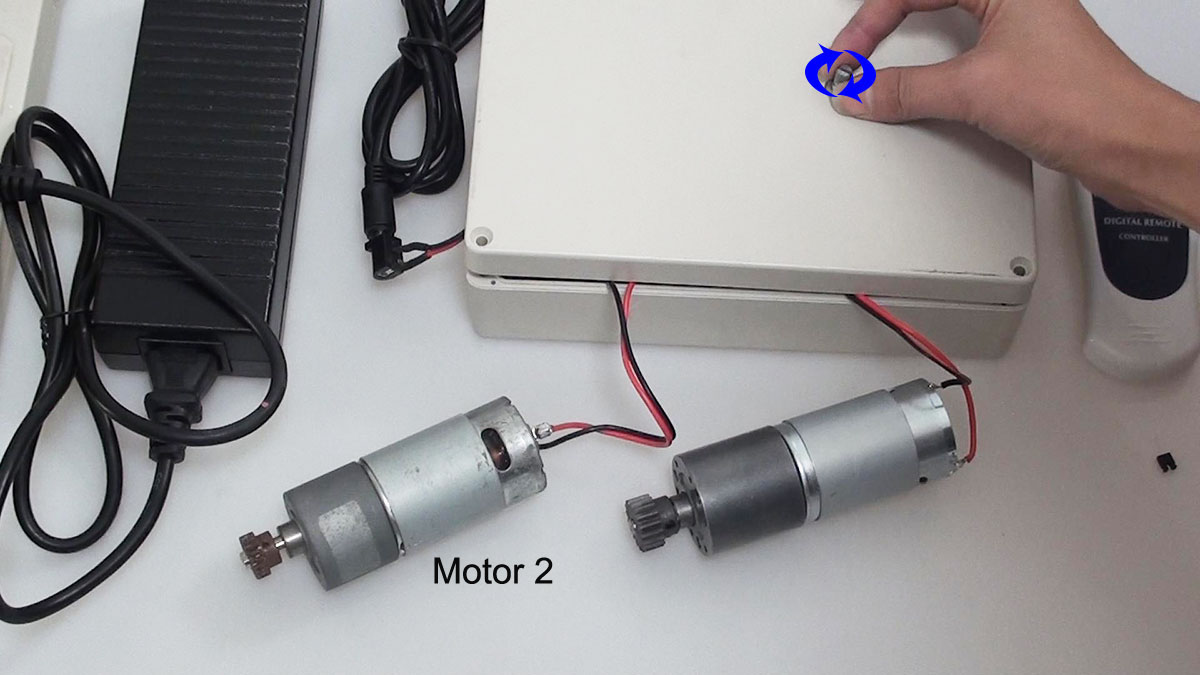

We will try to show you the demonstration of this motor controller. First of all we prepare RF receiver, transmitter, dc motor, 12V adaptor, and jumper.

According to the wiring diagram, we connect the motor to the “OUTPUT” terminal on the receiver and connect 12V adaptor to “INPUT” terminal.

At first, we try to control motor with manual switch. Setting control mode Momentary: Do not connect Jumper.

Press and hold button S3 on receiver: motor rotates in positive direction. Release button: motor stops.

Press and hold button S1 on receiver: motor rotates in reversal direction. Release button: motor stops.

Second, we try to use transmitter to control motor. We use another working mode “Latched’ Mode. Setting control mode Latched: Connect Jumper (CN1).

Press button ▲ on remote: motor rotates in positive direction.

Press button ■ on remote: motor stops.

Press button ▼ on remote: motor rotates in reversal direction.

Press button ■ on remote: motor stops.

Third, we control motor with limit switch. When rotation is overdone, we use limit switch to stop motor rotation. We start the motor positive rotation firstly. Connect SG2 and COM(short circuit of limit switch SG2), motor stops rotating. Disconnect SG2 and COM, motor rotates in positive direction again.

Press button ▼ on remote: motor rotates in reversal direction. Connect SG1 and COM(short circuit of limit switch SG1), motor stops rotating. Disconnect SG1 and COM, motor rotates in reversal direction again.

Operation Video:

Follow

Follow