The hydraulic lift is a device used to lift or bring down loads from one floor to another in multi-storeyed buildings or stereo garage car lifting. The hydraulic lifts are used widely in cars, containers, mold making, timber processing and chemical filling for purpose of different working height need. Maybe you just want to use small-sized hydraulic lift platform to do something and just want it to be remote controlled so that it can bring you more convenience.

Here you can use 1 channel momentary controller (S1FM-AC220+CV-2-2) to remote control your hydraulic lift up and down.

This kind of controller has inversion control mode. It is 10 amps of its maximum current and 500m working distance. The operation is also very easy.

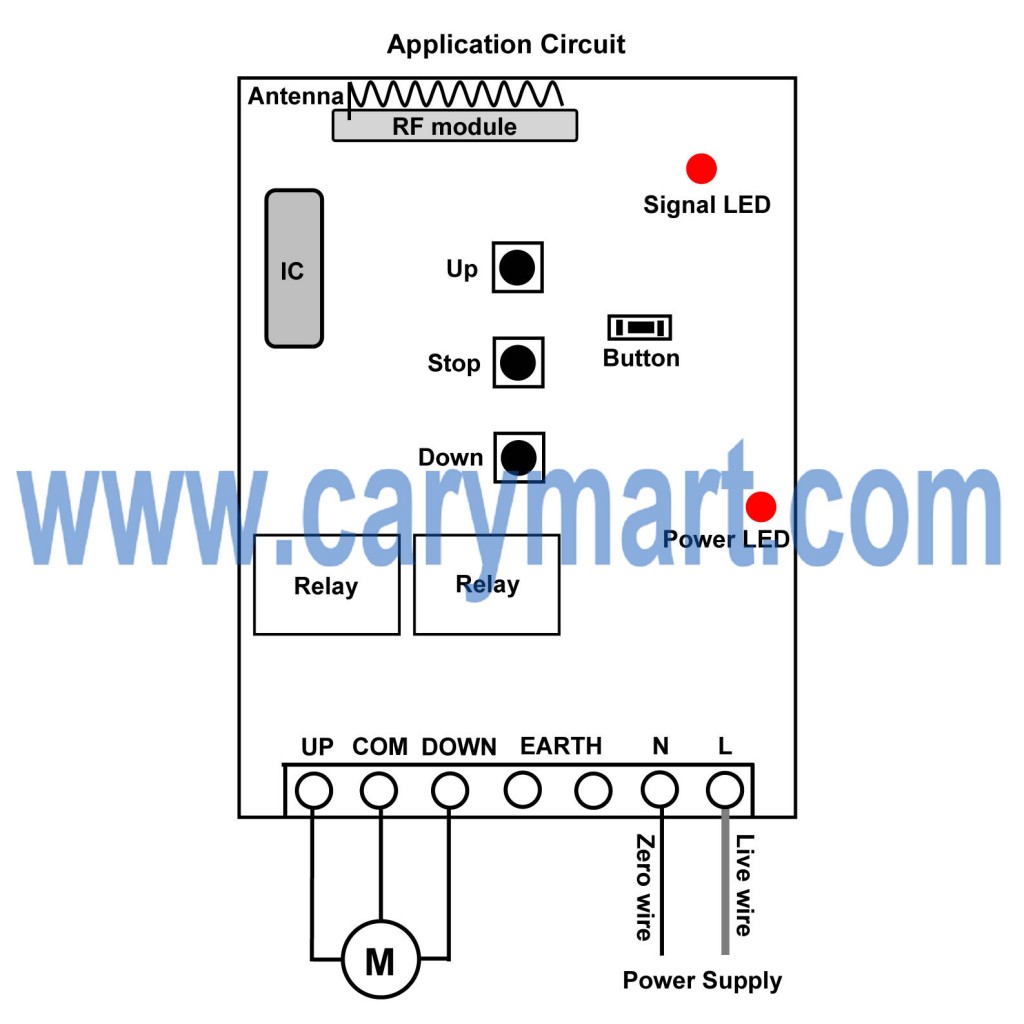

Connect live wire to terminal “L” and neutral wire to terminal “N”. Then connect AC motor to terminals “UP”, “COMMON” and “DOWN”. You can exchange “UP” and “DOWN” wires of motor to change the rotating direction of motor.

Press and hold button ▲ on remote or receiver: Terminals UP and COMMON directly output AC110V / AC220V; motor rotates continuously in positive direction.

Release button ▲ on remote or receiver: Stop the motor.

Press and hold button ▼ on remote or receiver: Terminals DOWN and COMMON directly output AC110V / AC220V; motor rotates continuously in reversal direction.

Release button ▼ on remote or receiver: Stop the motor.

Follow

Follow