The wireless remote control system is a device used to control the machine remotely, it was first developed by Nicola Tesla in the United States in 1898. There are two common remote control systems on the market, one is IR Remote Control, which is commonly used in various household appliances, such as TV and air conditioning; the other is the RF Remote Control, which is commonly used in anti-theft alarm equipment, door and window remote control, car remote control and so on.

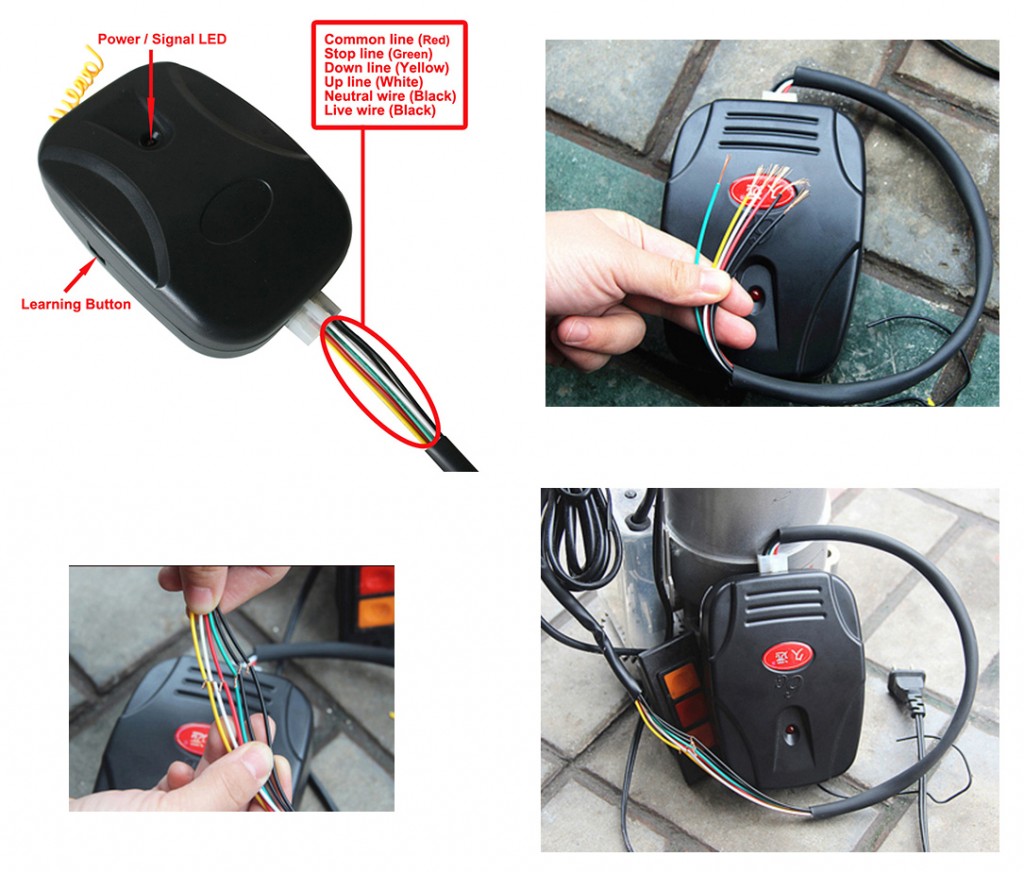

The radio remote control system (RF Remote Control) is a remote control device that uses radio signals to control a variety of equipment in the far distance. These radio signals can be received by remote receiving devices, which can drive all kinds of other mechanical or electronic devices to complete various operations, such as a closed circuit, mobile device and actuate motor. Radio remote control has been widely applied in the garage door, electric door, road gate remote control, burglar alarm, industrial control and wireless intelligent home.

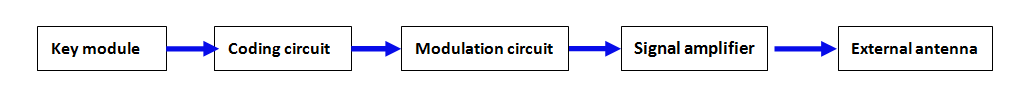

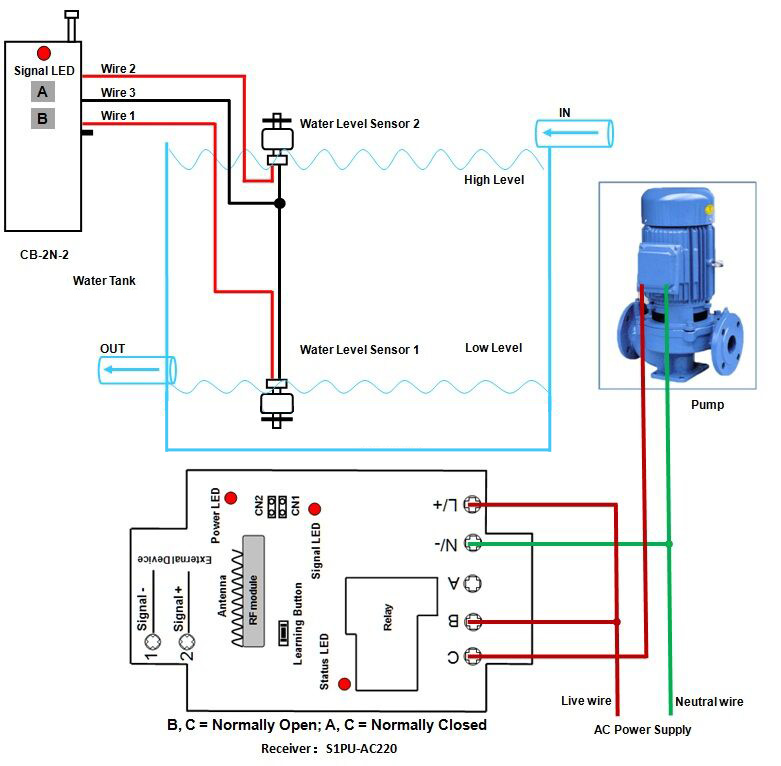

Radio remote controls system including a radio transmitter and a radio receiver. The transmitter mainly contains the coding circuit and the transmitting circuit. The coding circuit first generates the control instruction and then transmits the instruction signal to the transmitting circuit. The transmitting circuit loads the instruction signal on the high-frequency signal and then is sent to the wireless signal by the transmitting antenna. The receiver consists of a receiving circuit and a decoding circuit. Receiving circuit first amplifies the weak signal received, and then forwarded to the demodulator, the demodulators identify the signal, and then the amplifier circuit drives various devices.

There are two types of coding commonly used for radio remote control: fixed code and learning code.

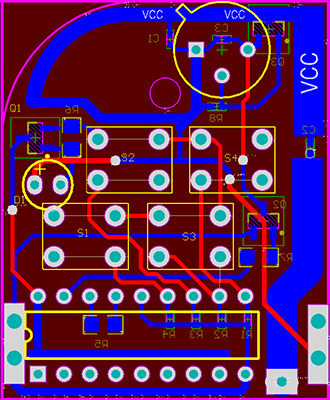

Fixed code:

- The fixed wireless remote control code using 2260/2262/2264 encoding chip, Its code is set by a soldering iron

- The coding capacity of the fixed code is 6561, so the amount of the code is limited, the probability of the code repetition is high.

- Mainly used for relatively low-security requirements of the occasion.

- If the user wants to increase the number of remote controllers, the new remote controller will be set to the same code as the old remote controller. The new remote controller and the old remote controller can work at the receiver at the same time.

- If the remote control is lost, the user can set the receiver together with the new remote control to a separate code so that the remote control can no longer be controlled and the receiver can no longer be controlled.

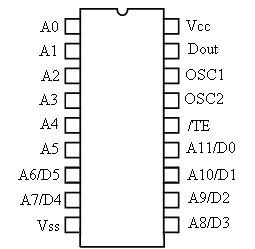

learning code:

- The learning code wireless remote control uses 1527/2240/101 and other coding chips, and the remote control does not need to be coded again when it is used.

- The encoding capacity of the learning code is 1 million, and the code repetition rate is low.

- It is mainly applied to occasions with higher safety requirements.

- If users want to increase the remote control, they only need to use the receiver to learn and store the code of the new remote controller, so the new remote controller and the old remote controller can work at the receiver at the same time. Usually, the receiver can store more than a dozen different codes.

- If the remote controller is lost, the user can use the receiver to delete the code of the old remote controller, then learn and store the code of the new remote controller, so that the lost remote controller can no longer control the receiver.

Follow

Follow